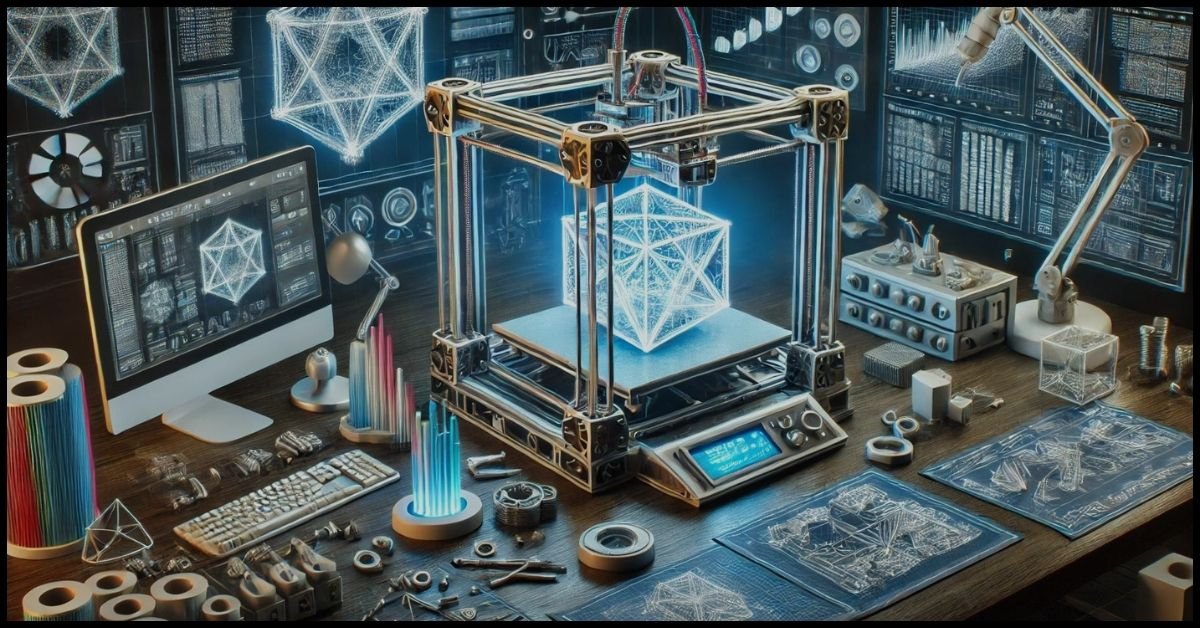

In the past decade, 3D printing and design have grown from niche technologies into significant forces driving innovation across various industries. From healthcare to architecture, 3D printing reshapes how products are designed, created, and manufactured. Whether you’re a beginner looking to explore the basics of 3D printing or a professional seeking to stay updated with the latest advancements, the 3d659.com Blog offers a comprehensive guide to the future of 3D printing and design.

Contents

The Evolution of 3D Printing Technology

A Brief History of 3D Printing

Additive manufacturing, another name for 3D printing, has been around since the 1980s. Initially, it was used primarily for prototyping, but as the technology matured, its applications expanded. Early 3D printers were limited by their slow speed and high cost, making them accessible only to large corporations. However, materials, software, and hardware advancements have made 3D printing more affordable and efficient.

Over the years, the shift from rapid prototyping to large-scale production has revolutionized industries. Today, 3D printing creates everything from customized medical devices to complex architectural models. As the technology continues to evolve, its potential applications are limitless, allowing for faster production times, reduced waste, and lower costs.

Key Milestones in 3D Printing Innovation

Several important milestones have marked the rise of 3D printing technology. One of the most notable is the introduction of Fused Deposition Modeling (FDM) in the late 1980s, which made 3D printing more accessible and scalable. The development of new printing materials, such as metal powders and biocompatible resins, has further expanded the possibilities of 3D printing.

More recently, 3D printing has become a key component in the aerospace, automotive, and healthcare industries. NASA, for instance, has successfully used 3D printing to create tools and parts for space exploration, while companies like General Electric are using it to produce jet engine components. In healthcare, 3D-printed prosthetics, implants, and organs transform patient care.

Current Applications of 3D Printing

3D Printing in Healthcare

One of the most promising applications of 3D printing is in the healthcare sector. Surgeons now use 3D-printed models to plan complex surgeries, improving precision and reducing risks. Custom 3D-printed implants and prosthetics offer patients personalized solutions that better fit their bodies, enhancing comfort and functionality.

Moreover, researchers are exploring the potential of bioprinting — using 3D printing technology to create living tissues and organs. While still in the experimental stages, bioprinting has the potential to revolutionize organ transplants, offering patients an alternative to long waitlists and donor shortages.

3D Printing in Architecture and Construction

3D printing creates detailed models and even full-scale buildings in architecture and construction. Architects can bring their designs to life with more precision and less waste. This technology allows for creating complex geometries that would be difficult or impossible to achieve with traditional construction methods.

3D-printed homes are becoming a reality in various parts of the world, providing a solution to housing shortages and disaster relief efforts. These homes can be built quickly, cost-effectively, and with a minimal environmental footprint, making 3D printing a game-changer for sustainable construction.

3D Printing in Manufacturing and Industry

In the manufacturing world, 3D printing has the power to streamline production processes, reduce lead times, and lower costs. This technology allows companies to create prototypes rapidly, iterate designs more efficiently, and move from concept to production in a fraction of the time compared to traditional manufacturing methods.

3D printing is also transforming supply chains by enabling on-demand production. This reduces the need for extensive inventories, cuts shipping costs, and minimizes waste. In particular, the automotive and aerospace industries are leveraging 3D printing to produce lightweight, durable parts, improving overall performance while cutting costs.

The Future of 3D Printing: What Lies Ahead?

Sustainable 3D Printing

As industries prioritize sustainability, 3D printing is emerging as a key player in reducing waste and environmental impact. Traditional manufacturing methods often involve subtractive processes, where excess materials are discarded. In contrast, additive manufacturing builds objects layer by layer, using only the necessary material.

Researchers are also developing eco-friendly 3D printing materials, such as biodegradable plastics and recycled composites. This trend toward sustainability is expected to grow, with 3D printing playing a central role in creating greener production processes across various industries.

The Impact of AI and Machine Learning on 3D Printing

Artificial intelligence (AI) and machine learning are increasingly integrated into 3D printing systems to enhance efficiency and accuracy. AI can analyze vast amounts of data to optimize printing parameters, reduce material usage, and improve the quality of printed objects. With AI-driven 3D printing, manufacturers can produce highly complex and customized parts with greater precision.

Moreover, AI can predict potential errors in the printing process, allowing for real-time adjustments and reducing the likelihood of costly mistakes. As AI and 3D printing technologies evolve, we can expect even more significant automation, customization, and efficiency advancements.

How 3d659.com Blog Can Help You Stay Informed

Expert Insights and Tutorials

Whether you’re new to 3D printing or a seasoned professional, the 3d659.com Blog offers many resources to help you stay informed. The blog features expert insights, in-depth tutorials, and the latest industry news, providing readers with valuable information on everything from beginner tips to advanced techniques.

Industry Trends and Innovations

The 3d659.com Blog also covers the latest trends and innovations in 3D printing, keeping you updated on the industry’s future. From new materials and technologies to emerging applications, the blog comprehensively covers what’s happening in 3D design and manufacturing.

Community and Collaboration

The 3d659.com Blog fosters a community of 3D printing enthusiasts, designers, and professionals. By engaging with the blog’s articles, readers can connect with others who share their passion for this exciting technology, exchange ideas, and collaborate on projects.

FAQs

What is 3D printing, and how does it work?

3D printing, also known as additive manufacturing, is a process where digital models are used to create three-dimensional objects by adding material layer by layer. It works with various materials, including plastics, metals, and resins, and is widely used in industries like healthcare, construction, and manufacturing.

How is 3D printing used in healthcare?

3D printing creates customized implants, prosthetics, and surgical models. It allows for precise planning of complex surgeries and offers patients more personalized medical devices. Researchers are also exploring bioprinting to create living tissues and organs.

What are the benefits of 3D printing in manufacturing?

3D printing streamlines the production process by enabling rapid prototyping, reducing lead times, and lowering costs. It also allows for on-demand production, minimizing waste and reducing the need for extensive inventories.

What materials are used in 3D printing?

3D printing can use various materials, including thermoplastics like PLA and ABS, resins, metals such as titanium and stainless steel, and biodegradable or recycled materials. The choice of material depends on the final product’s specific application and desired properties.

What is the future of 3D printing?

The future of 3D printing is promising, with advancements in AI integration, sustainable materials, and large-scale construction. As the technology evolves, we can expect more industries to adopt 3D printing for its efficiency, customization options, and cost-saving potential.

How can I learn more about 3D printing?

You can learn more about 3D printing by visiting the 3d659.com Blog, which offers a range of tutorials, expert insights, and industry updates. Whether you’re a beginner or an expert, the blog provides valuable information to help you stay informed and expand your knowledge of 3D printing.

Conclusion

3D printing and design are evolving rapidly, with new technologies and applications emerging astonishingly. As industries continue to adopt 3D printing for everything from healthcare to architecture, the potential of this technology is limitless. The 3d659.com Blog is your go-to resource for staying informed about the latest advancements, trends, and innovations in 3D printing. Whether a hobbyist or a professional, you’ll find the insights and knowledge to navigate the exciting world of 3D printing and design.